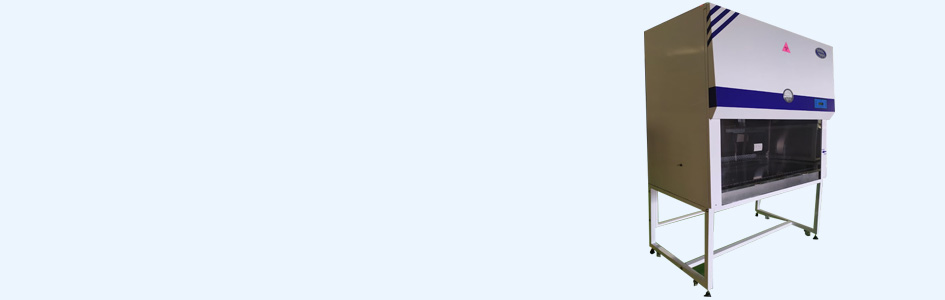

Class II Biosafety cabinet – Type B2

- Aeromech™ Class II Type B2 cabinet all inflow and downflow air is exhausted after HEPA filtration to the external environment without recirculation within the cabinet. Type B2 cabinets are suitable for work with toxic chemicals employed as an adjunct to microbiological processes under all circumstances since no re-circulation occurs. In theory, Type B2 cabinets may be considered to be the safest of all Class II biological safety cabinets since the total exhaust feature acts as a fail-safe in the event that the downflow and / or exhaust HEPA filtration systems cease to function normally. However, Class II Type B2 cabinets are, in practice,difficult to install, balance and maintain.

| 1 | Product | Class II Bio safety Cabinet –Type B2 |

| 2 | Air balancing | 0% recirculation.100% exhaust |

| 3 | Protection | Product & Personnel & Environmental protection |

| 4 | Bio safety Level | Bio safety Level 1 , 2 & 3 |

| 5 | Exhaust Duct Requirement | Hard Duct Only |

| 6 | Control Plenum surrounded by | Negative Plenum |

| 7 | Cleanliness level | ISO class 5 as per ISO 14644-1 |

| 8 | Average Airflow | Inflow Velocity - Minimum 0.45 m/s ( 90 FPM) at 8” front opening |

| Velocity | Down Velocity - 0.30 m/s ( 65 FPM) | |

| 9 | Noise level | 60 db on A scale |

| 10 | Light Intensity | Minimum 900 lux inside the working area at ambient zero |

| 11 | MOC | Main Body - Galvanized Iron with PU coated / Stainless Steel – Satin Finish Working Area - Stainless Steel IS 304 Grade Satin Finish |

| 12 | Supply Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 13 | Exhaust Filter | HEPA Filter having EU 13 rating with suitable size. |

| Efficiency | 99.99% down to 0.3 Microns. | |

| 14 | Pre Filter | Aeromech® make, EU 4 rating with suitable size. |

| Efficiency | 90% down to 10 Microns. | |

| 15 | Noise Level | Less than 70 db 'A'. |

| 16 | Vibration Level | Minimum. |

| Instrumentation | ||

| 17 | Differential Pressure Gauge | Magnehelic Gauge - 01 No. (make : Dwyer, USA) with each unit (To measure differential pressure across the supply HEPA filter). |

| Motor Blower Assembly | Statically & Dynamically balanced with suitable rating and size. | |

| 18 | Supply & Exhaust | (Induction motor with centrifugal blower) A Mounting unique spring suspension system to take care of vibration and noise. |

| 19 | 3 Pins Switch & Socket | 15 AMPS - 1 set in each unit. |

| 20 | Other Switches | On/Off switches for motor blower & CFL lights. |

| 21 | Microprocessor Control | Airflow display and UV Interlocking and Low airflow Alarm and Supply & Exhaust filter Fail |